Current Scenario of Furniture Industry in Malaysia

Malaysia's development in the furniture industry was admirable over the last three decades, where it begins from gentle cottage-based starting into a multi-billion-dollar export-oriented industry. Malaysia was categorized as one of those fastest-growing countries producing furniture within the sub-sector of the wood-based industry. Currently, Malaysia was actively competing with China as well as Vietnam in producing inexpensive nations in terms of the wood-based furniture industry. The value-chain which consists of innovation and value-addition of Malaysian furniture industry needs to revolutionize and stride forward so that Malaysia can remain competitive with those countries. In fact, due to the export amount of approximately 2.1 billion USD, it makes Malaysia was ranked as the 9th largest furniture exporter in the world in 2017. Approximately, 85% of Malaysia’s exports have reached over 160 countries all over the world and have exceeded its annual production volume as well as indirectly make Malaysia as large export-oriented furniture manufacturing (Ratnasingam, 2018).

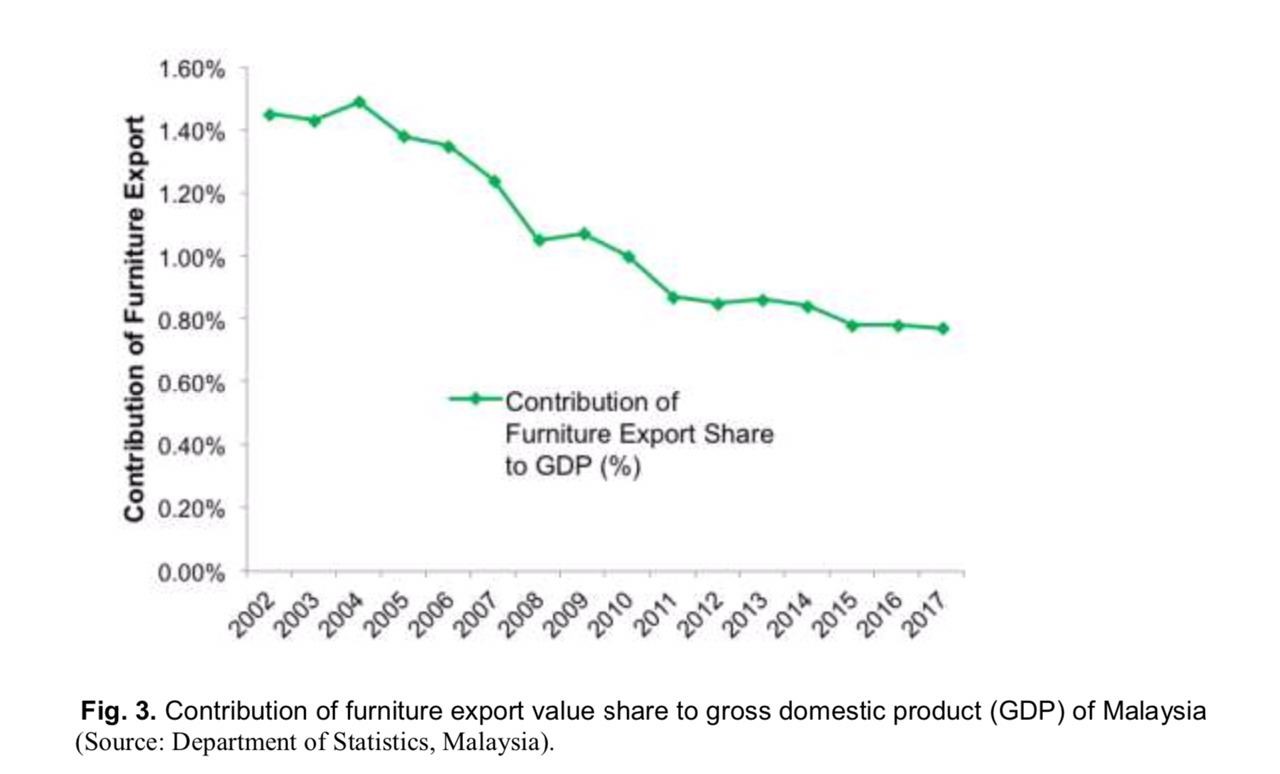

According to (Ng and Ratnasingam, 2018), the Malaysia furniture industry was known as a matured industry due to it shows friendly and positive development despite faced some issues and challenges encountered by the industry. This can be seen by referring to Figure 1 where the trend of furniture export value from Malaysia was reducing and declining. This issue rises due to expanding labor costs and a diminishing supply of rubberwood.

Fig. 1. Contribution of furniture export value share to gross domestic product (GDP) of Malaysia

(Source: Department of Statistics, Malaysia)

To overcome those issues, Malaysian need to make innovation and creativity in terms of the product either goods or services, process as well as advanced marketing approach and a modernized administrative pattern in business processes. One of the innovations that can be made to ensure Malaysia's wood industry was in parallel with the development of technologies was producing cross-laminated timber (CLT). The CLT has drawn global attention because of its superior structure which was an appeal for construction components of the aged continent. This laminated timber became favorable and attractive in the building system due to saving labor cost and minimum interruption to the site’s ambiance. The most desirable element about CLT where it’s potential that can be used to build a tall building as well as story buildings that have been building. Moreover, in some aspects, CLT was also known as comparable as well as excellent towards steel and concrete as well as in term of a building structure, it grants long life span without intermediate support. Malaysia’s industry can enhance its production by producing a product that has higher market demand worldwide and seek an opportunity to produce a product that appealed to advanced technologies.

Moreover, when wood was disclosed to weather and moisture frequently, the chances of wood to degrade rapidly was high due to the presence of various organisms and abiotic factors. Consequently, to increase the service life of wood, the preservations method need to be developed so that replacement costs can be reduced as well to ensure the wood can be efficient in various application. The wood preservation that can be developed and applied in Malaysia’s furniture industry was using nanotechnology in wood preservation. The nanosized metallic such as copper, silver, and zinc oxide can be immediately practiced to wood through a vacuum pressure operation. According to (Matsunaga et al., 2009), when comparing with conventional formulations, the nanotechnology wood preservative has an extending level of penetration as well as a greater amount of homogeneous uptake particles of wood. Besides, better water dispensability and assure form protection enabled when the encapsulation of hydrophobic biocide with nanocarriers. The coating treatment by applying numerous nanomaterials can enhance the surface modification so that it can oppose weathering as well as enhancing its hydrophobicity in which this process was a so-called modification of wood. (Hubbe et al., 2015).

In a nutshell, the desire for innovation and creativity in Malaysia’s wood-based industry was essential for the sustainable growth of the industry. Malaysia furniture industry needs to expand their networking and collaborate with many experience countries such as Indonesia so that can learn and produce a product that can fulfill customer desired and needs as well as has its unique value.

REFRENCES

Hubbe, M. A., Rojas, O. J., & Lucia, L. A. (2015). Green modification of surface characteristics of cellulosic materials at the molecular or nano scale: A review. BioResources, 10(3), 6095-6206.

Matsunaga, H., Kiguchi, M., & Evans, P. D. (2009). Microdistribution of copper-carbonate and iron oxide nanoparticles in treated wood. Journal of Nanoparticle Research, 11(5), 1087-1098.

Ng, B. K. (2011). Technological innovation patterns among Malaysia's small and medium-sized wooden furniture manufacturers: a sectoral innovation systems perspective/Ng Boon Kwee (Doctoral dissertation, University of Malaya).

Ratnasingam, J., Chin, K. A., Latib, H. A., Subramaniam, H., & Khoo, A. (2018). Innovation in the Malaysian furniture industry: Drivers and challenges. BioResources, 13(3), 5254-5270.

Prepared by,

Ms. Nur Afira Badrul Hisham

Ts. Dr. Sharizal Ahmad Sobri CEng

/alumni.png)